The aim was to determine the effectiveness of the cooling system and to identify the optimal pcm beeswax or rubitherm rt 44 hc for a temperature range of 25 55 c.

Phase change material for battery cooling.

The phase transition may also be between non classical states of matter such as the conformity of crystals where the material goes.

An encapsulated thermal battery is physically similar to a phase change thermal battery in that it is a confined amount of physical material which is thermally heated or cooled to store or extract energy.

However in a non phase change encapsulated thermal battery the temperature of the substance is changed without inducing a phase change.

14 was a small battery system build by schweitzer and al hallaj utilizing phase change component pcc material to surround commercial cylindrical 18 650 lithium ion cells.

A pcm is a substance that is good at absorbing large amounts of heat energy while melting from solid to liquid and then releasing the energy while freezing back into a solid.

Thermal energy storage can be used to increase the cooling capacity of the power plant during these hot days while using the cold air at night to recharge the phase change material.

Generally the transition will be from one of the first two fundamental states of matter solid and liquid to the other.

This load shifting to cooling at nighttime temperatures is done in order to improve the cooling capacity of air cooled condenser acc systems.

A phase change material pcm is a substance which releases absorbs sufficient energy at phase transition to provide useful heat cooling.

These dual functions are examined by discharging experiments of lithium iron phosphate battery at room temperatures t 0 10 c 25 c and 40 c.

Battery thermal management phase change material battery thermal characteristics active cooling 1.

The chicago based firm allcell technologies thinks it may have a better solution.

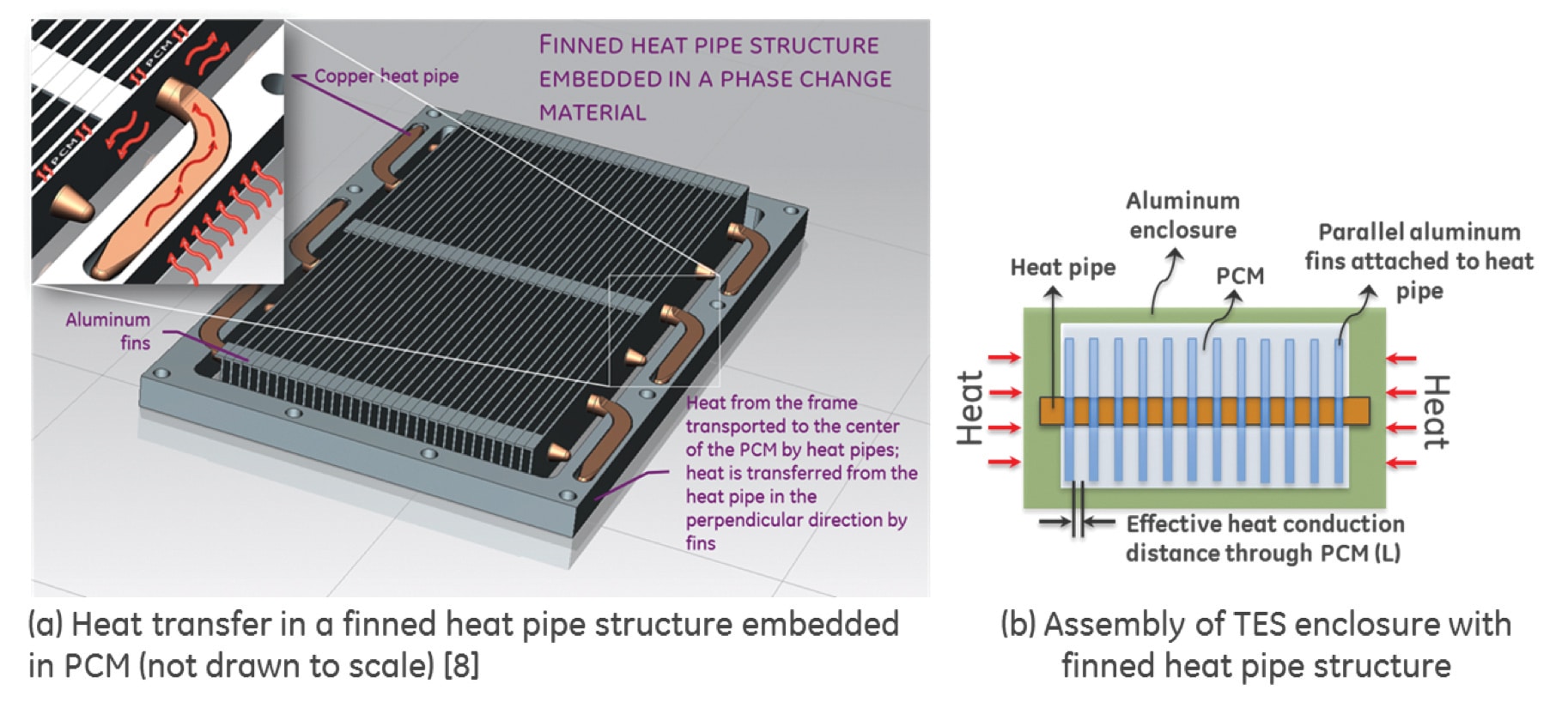

Different from previous work this design integrates phase change material heat pipe and spray cooling and can offer both heating and cooling services on demand for lithium ion battery.

But because of the heavy weight the system need to be optimized with a balance of the cooling capacity contributed by the active and passive cooling.

The battery module used in fig.

The hybrid system that integrates active cooling into phase change materials pcms expanded graphite eg shows great prospects for power battery thermal management.

The idea proposed by the authors was to analyze different pccs in terms of thermal performances.